I have been running a direct drive wheel since May 2014. How come I went with that investment? A friend of mine had just gotten a Leo Bodnar SimSteering v1 and once I found out, I asked whether I could have a test drive at his place. After a few hours testing at his place it was clear: If ever I would get another wheel, it had to be one of those! Everything felt much stronger initially – which should not come as a surprise when switching from 3Nm to 16Nm! But as the test went on, I noticed a number of other things:

- everything seems much more “connected” and more intuitive

- more detail can be felt at low and high load / grip levels thanks to the higher dynamic range

the limit of grip was easier to find - cars are much easier to drive over the limit

So with that in mind, once my wheel broke down I finally hit the order button and set up my own SimSteering v1 a few days later.

Fast forward to late 2018, I had been using the SimSteering for just shy of 4.5 years. Issues? Not a single one. Regardless of that, I was very excited to hear that I’d get one of the early prototypes of the VRS direct drive wheel (which at the time did not have a name yet!). The VRS wheel was intended to deliver top quality at an unbeatable price and I was eager to see if it could really achieve that.

Since it was an early prototype, I didn’t commit to immediately replace my SimSteering but rather set up a secondary rig to mess around with the VRS controller. And as one could expect, dealing with early prototypes means that things may go wrong from time to time. Some issues could fortunately be fixed just in firmware, other required some modifications to the hardware itself.

Aside from initial hardware compatibility issues, the first significant problem for me was the smoothness of the FFB. It was either very notchy or – when filtered – it became dull and at times felt like there was a little bit of lag. Fast forward another 5 or 6 weeks. The FFB issue was rectified by a combination of some more clever filtering in the firmware and hardware updates. The controller was now running more reliably and it was time to do a more direct comparison to my SimSteering wheel.

The newer version of the hardware came with a set of cables for my Kollmorgen AKM52 motor (the one from the SimSteering unit). During the following 3 weeks, I switched back and forth between the Leo Bodnar and the VRS controller, trying to find differences. Once firmware matured, the controllers behaved so similarly that I could not really tell which one is which (apart from an obvious difference in boot up procedure). As far as I was concerned, the VRS controller was now at a level that is just as good as the SimSteering.

At this point, I was also eager to address the only minor flaw I found in my v1 SimSteering wheel – the lower resolution encoder – which affects the feel of the damping effect. The SimSteering v2 fixes that by using a high resolution resolver, however, I could never justify the upgrade cost. From my earlier testing of the VRS controller on my secondary rid, I knew that the damping effect felt much smoother on the MiGE motor thanks to its high resolution BISS-C encoder. So, in early 2019, the AKM motor on my primary rig was replaced by the MiGE motor and I’ve been using it with my VRS DirectForce Pro controller ever since.

A common question in the sim racing community is: Which direct drive wheel is better? Most of my teammates use a direct drive wheel from several different makers. In our collective experience, any properly configured high-end direct drive system – driven by a proper servo motor (not a stepper) and coming from a top vendor – would be nearly indistinguishable from a competitive systems of similar specs. At the end of the day, the job of the wheel is to quickly and accurately execute the torque command issued by the sim, so by definition, they should feel the same. Of course, there are different filters or user settings available, but all of these are subjective and in the personal preference category. There are other small considerations such as size of the controller, noise from fans/controller/motor but these do not impact the feel of the FFB. And a big consideration for almost everyone is cost. VRS DirectForce Pro is certainly up there with the best direct drive controllers and if it can deliver on the “unbeatable price” premise, it would likely be the go-to direct force wheel for a lot of people.

If you’d like to get updates about the VRS Hardware initiative, follow our Facebook page, or register to our hardware mailing list here.

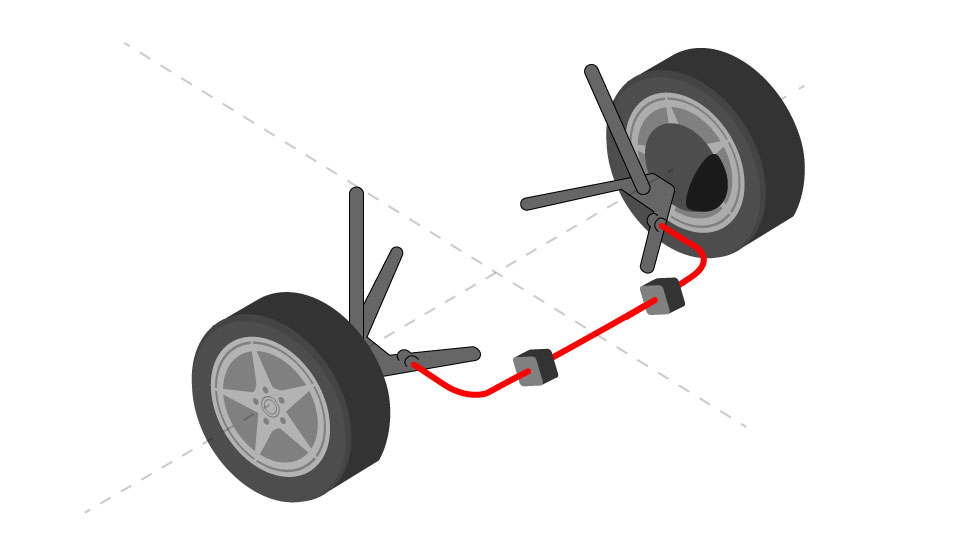

The differential (or diff, for short) allows the left and right wheels to rotate independently, which helps balance the car through corners. Its configuration determines how much of the torque coming off the engine is transferred to each wheel. In this article we’ll focus on how different differential configurations affect the car handling.

The differential (or diff, for short) allows the left and right wheels to rotate independently, which helps balance the car through corners. Its configuration determines how much of the torque coming off the engine is transferred to each wheel. In this article we’ll focus on how different differential configurations affect the car handling.  A spool gives you good traction accelerating on a straight line, but the handling of the car is compromised during turning. When going around a corner, the outside tire has to travel a longer distance. So, the inside is forced to rotate faster than it needs for the turn radius and hence spins. This causes stress (wear) on both tires and the drive train. In terms of handling, this causes understeer when decelerating, and oversteer when accelerating.

A spool gives you good traction accelerating on a straight line, but the handling of the car is compromised during turning. When going around a corner, the outside tire has to travel a longer distance. So, the inside is forced to rotate faster than it needs for the turn radius and hence spins. This causes stress (wear) on both tires and the drive train. In terms of handling, this causes understeer when decelerating, and oversteer when accelerating.

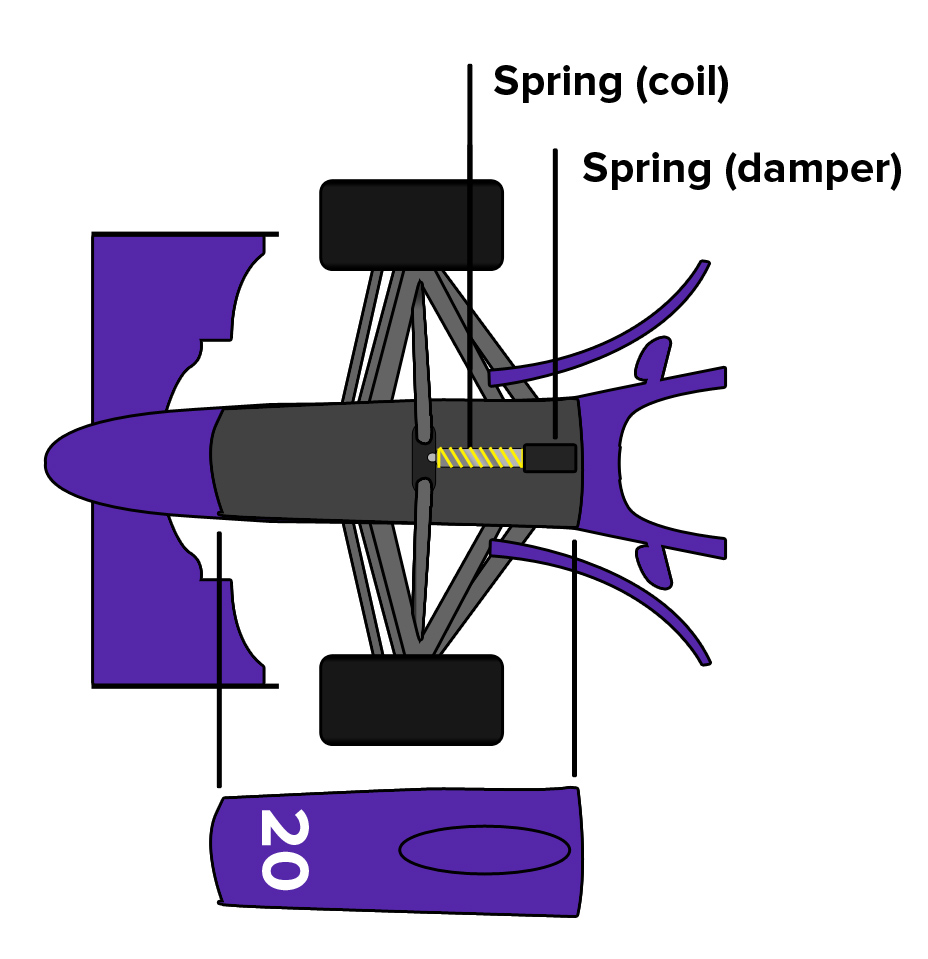

Static ride height is one of the key setup adjustments, and also one of the easiest to get right. For example, for many cars converting a qualifying setup into a race setup (or vice versa) only means adjusting fuel and the static ride height. In this article we’ll explain what ride height entails, how you can adjust it, and how it affects other setup adjustment.

Static ride height is one of the key setup adjustments, and also one of the easiest to get right. For example, for many cars converting a qualifying setup into a race setup (or vice versa) only means adjusting fuel and the static ride height. In this article we’ll explain what ride height entails, how you can adjust it, and how it affects other setup adjustment.

(If you haven’t read article

(If you haven’t read article

After the tyre pressures, which we handled in

After the tyre pressures, which we handled in

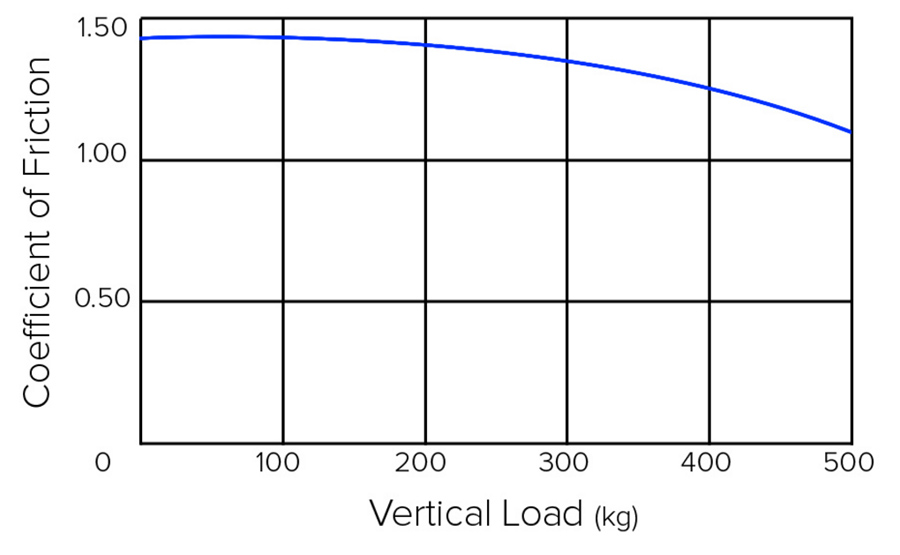

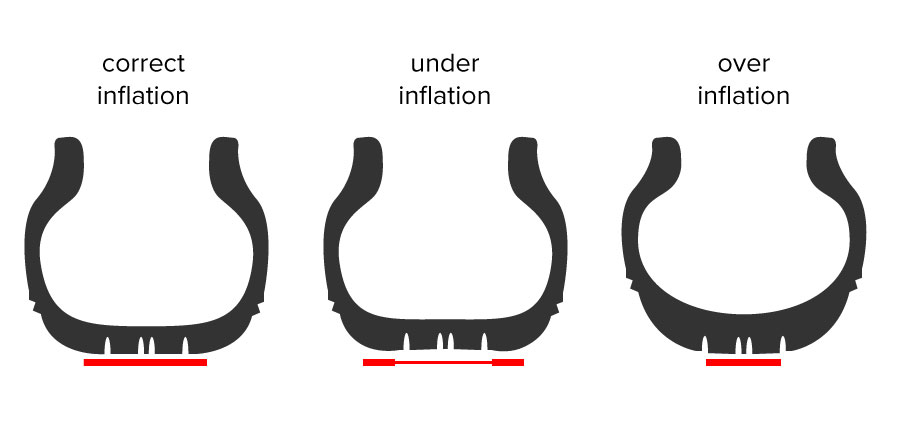

One of the few setup options available to the Skip Barber car is the pressure in the tyres. It’s also one of the most important things to get right on every single car. To find the ideal tyre pressure, it’s important to know what to look out for.

One of the few setup options available to the Skip Barber car is the pressure in the tyres. It’s also one of the most important things to get right on every single car. To find the ideal tyre pressure, it’s important to know what to look out for.

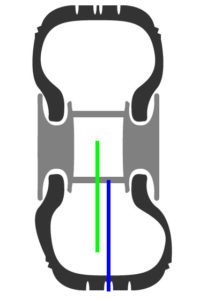

Moreover, lower tyre pressures also affect the lateral stiffness, and when running very low pressures, it’s possible that the middle of the tyre is no longer at the centre of the rim while cornering. It can cause the sidewalls of the tyres to nearly fold. This is also not ideal (see image).

Moreover, lower tyre pressures also affect the lateral stiffness, and when running very low pressures, it’s possible that the middle of the tyre is no longer at the centre of the rim while cornering. It can cause the sidewalls of the tyres to nearly fold. This is also not ideal (see image). As you progress through your iRacing career, competition is fiercer and you’ll need to use all the tools in the box to find the edge over your rivals. One of these tools is car setup. And while most beginner series have friendly communities with lots of setups being shared on the forums, the willingness to share setups significantly drops off at more competitive series. Especially at the top level of sim racing, setups are seen as highly guarded intellectual property. Thus, having a basic understanding of car setups becomes a very useful asset in your sim racing career.

As you progress through your iRacing career, competition is fiercer and you’ll need to use all the tools in the box to find the edge over your rivals. One of these tools is car setup. And while most beginner series have friendly communities with lots of setups being shared on the forums, the willingness to share setups significantly drops off at more competitive series. Especially at the top level of sim racing, setups are seen as highly guarded intellectual property. Thus, having a basic understanding of car setups becomes a very useful asset in your sim racing career.  In the following series of blog posts we’re trying to shed some light on the various hardware parts you need to have or – for some parts – should have. To make the chunks of information a little smaller and easier to digest, this is split into the multiple posts. See also ‘

In the following series of blog posts we’re trying to shed some light on the various hardware parts you need to have or – for some parts – should have. To make the chunks of information a little smaller and easier to digest, this is split into the multiple posts. See also ‘